Products

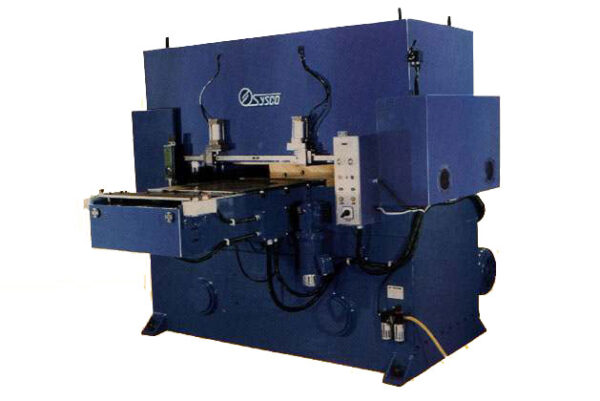

Jigsaw Puzzle Auto Cutting Machine (FH3539-150)

Description

This Full Head Press Cutting System features 150 tons of available tonnage and a 35″ x 39″ bed size.

Features

Features

A four-post hydraulic press producing 150 metric (165 U.S.) tons of cutting force, with two cylinders mounted over cross members linked end to end with torsion bars. This mechanical balancing system ensures that the maximum cutting force of the press can be delivered anywhere on the bed of the press, and keeps the bed and bridge parallel even under asymmetrical (unbalanced) loads. This hydraulic press can deliver its total force at any point in the down stroke.

Advantages

- Twin cylinder, four column cunstruction with double mechanical balancing mechanism and reinforced full head ensure even cutting death for congested cutting dies.

- Blade downward cutting die mounted under head and material placed on steel sliding table achieve easy material loading and cutparts collecting.

- High precision four post mechanical stops and hrc 60° german steel plate ensure perfect kiss cutting and through cutting results.

- Manual four post mechanical stops for accurate bottom position control.

- Cutting against HRC 60° hardened and ground steel plate.

- Single auto steel slide table with frequency converter cushion system.

- Front four cell photocell safety guard and rear fix guard.

- Pneumatic fix die rails under head.

- Much more durability of the cutting die.

- Working capacity of 4000 to 6000 cuts per eight hours

Range of Applications

- Auto cutting of sheet type material, cutting force required is six tons per meter cutting die for two mm thick paper puzzle material.

- P.P. cutting pad with pad shifter and two projector lamps instead of german steel plate for through cutting only. You can get better cutting results from uneven die height.

Options

Specifications

| Cutting Force: | 165 Tons (150 Metric Tons ) |

| Cutting Stroke: | 4.3” (110 mm) |

| Maximum Daylight: | 6.3” (160 mm) |

| Machine Bed: | 26"D x 32"W (660 x 812mm) |

| Main Motor: | 20 HP |

| Gross Weight: | 9900 Lbs (4500 Kgs) Approx. |

| Series: | FH2632-150 |