Products

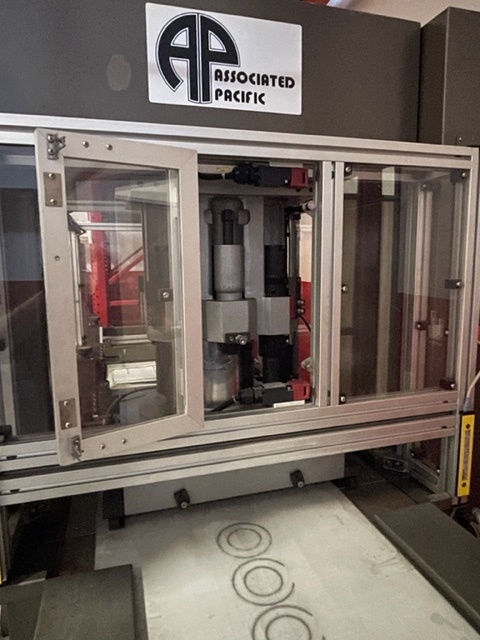

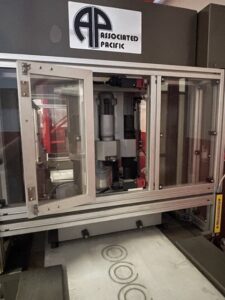

High Speed Die Cutting Press (HS-25 Tons) AP-10705C

Description

Associated Pacific Machine offers a wide variety of automated die cutting machinery. Here are some of the machines we offer:

Swing Arm, Traveling Heads, Full-heads, and Receding Heads.

Features

Features

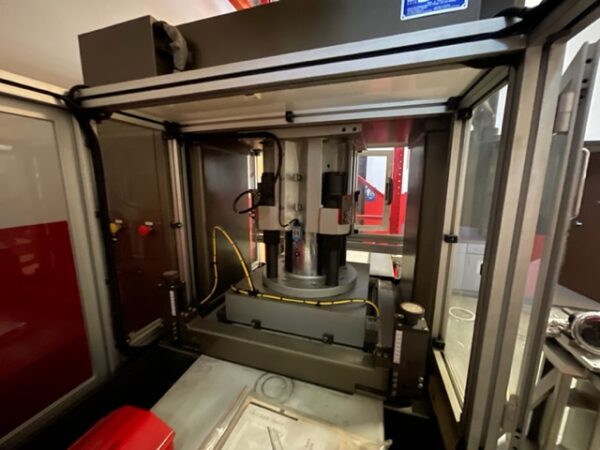

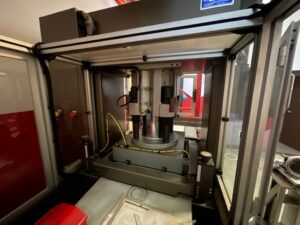

The single cylinder High Speed press has a welded steel construction for superior rigidity and strength. This completely automated die cutting system is user friendly and is specifically designed to achieve high production rates for kiss cutting and through cutting. The hydraulic system is designed for low noise, optimum efficiency, and low electricity consumption.

- Manual 4 Position Mechanical Stops – Low point stops ensure the precise bottom position and parallelism of the head on each cutting stroke. There are four adjustable stops located in the head of the press. They correspond to the four corners of the head. When one stop is adjusted all stops are adjusted at the same time.

- Pneumatic Die Mounting Rails Under the Head – The die rails hold the tooling under the head. They are pneumatically operated and fully adjustable for easy die board change out.

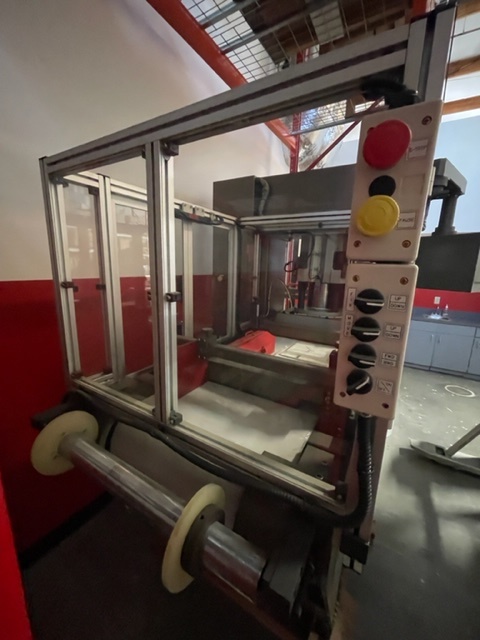

- Cutting on Polyester Belt System – A cutting belt system consists of a number of components. The belt goes through the press and acts as both a transport system and cutting surface. Normally the belt is divided into three different sections. There is usually an in-feed section; its length will vary depending on the depth of the press, if the material is in sheets or rolls and the desired feed length. Underneath the cutting head is the cutting section of the belt. After the cutting section is the outboard section for cut parts removal. The belt travels through the press and underneath to make a loop. A belt shifter is used in the design to increase belt life. Mechanical stops are used to control the cutting depth, also to increase belt life and prevent belt damage. This is important with cutting on a belt system. Belt movement is controlled by a clamping beam. A used polyester cutting belt, gravity roller and belt shifter are included. Belt size: 420Wx6000Lmm.

- Inboard Clamping Beam Feeding System – Takes the incoming material and moves it toward the press. The rear clamp which is moveable grips the material and moves it forward on a conveyor belt. When the material is under the press, the fixed position clamp closest to the machine clamps down and holds the material while the moveable clamp returns backwards in preparation for the next feed.

- 1 HP Servo Motor Positioning System – The servo motor positioning system has a +/-0.004” positioning accuracy which means you will obtain very high material yields. The system consists of an AC servo motor, encoder, and integrated drive unit.

- High Speed Hydraulic System – A special hydraulic system so the press can make more cuts per minute than it would make with a normal hydraulic system.

- Touch Screen Operator Interface with Program Storage – The user friendly touch screen makes machine operation easy for any operator with the ability to store programs, recall programs, and change material specifications and feed distances all with the touch of a finger. It also contains information from the operator’s manual on how to do a die setting, set the mechanical stops and trouble shooting. The program memory can be up to 100 programs.

- Inboard Fence and Outboard Hinged Safety Guards

Specifications

| Cutting Force: | 28 Tons (25 Metric Tons) |

| Cutting Stroke: | 5.1" (130mm) |

| Maximum Daylight: | 6.1" (155mm) |

| Head Size: | 19.7” D x 19.7” W (500 x 500 mm) |

| Main Motor: | 5 HP |

| Gross Weight: | TBD |

| Series: | HS- 25 Tons |