- Machinery

- Stock & Used Machinery

- Accessories

- Parts & Service

- Applications

- News

- About Us

- X

- No products in the list

- Machinery

- Stock & Used Machinery

- Accessories

- Parts & Service

- Applications

- News

- About Us

- X

- No products in the list

Skip to content

- Machinery

- Stock & Used Machinery

- Accessories

- Parts & Service

- Applications

- News

- About Us

- X

- No products in the list

Products

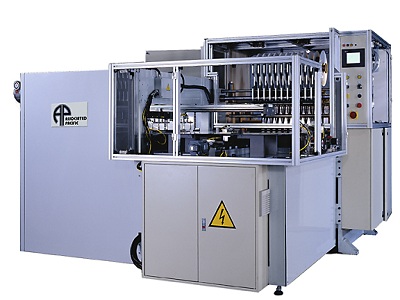

Automatic Magnetic Tape Laying Machine with Auto Loader (MTL-700NSA)

Description

Machine For Sheet To Sheet Application With Auto Loader

Features

Advantages

- The machine can operate at the highest possible speed. Material type and thickness can affect the speed at which you can run the machine.

- The pressure and heat of each laying roller press are individually controlled, minimizing the surface area subjected to heat, as well as allowing for fine tune adjustments.

- The multiple pinch rollers hold the material securely in place throughout the application process, allowing for perfect parallelism of the magnetic strips.

- The operation area is entirely enclosed by clear glass safety doors, allowing for operator safety, without decreasing the visibility of operation.

- User friendly touch screen control.

- Automatic operation.

- Exact placement of magnetic tape on blank stock.

- Uses registration marks to place the magnetic tape on printed/unprinted material.

- Sheet size up to 40″ x 40″.

- Multiple magnetic tracks.

- CR 80 cards, hang tags, plus other applications.

- Material range from 10 mil – 30 mil or thicker.

- Auto sheet feeder holds approxiamtely 750 sheets, with sheet thickness of 30 mil.

Range of application

-

The purpose of the machine is to place magnetic tapes onto plastic or paper card sheet materials. The materials can be PVC, Styrene, PET, PETG, or any other sheet material suitable for plastic card production. The material can be roll sheets, press polished, or laminated. The material thickness can range from 10 to 30+ mil. The tape can be lo-co or hi-co.

Options

Machine Options

- Machine can be designed with auto stocking (sheets stack up at the end on pallets) or on a kilt table (approx. 150 sheets per stock load)

- Increase in the number of tapes

Specifications

| Compressed Air: | 6 bar |

| Dimension: | 108.3"L x 96.5"W x 73"H (2750L ×2450W ×1855H mm) |

| Magnetic Tape Width: | Standard ISO or any custom sizes |

| Motor Servo: | 1HP |

| Gross Weight: | 6000 Lbs (2727 kg) |

| Number Of Tapes: | 8 (Optional up to 15) |

| Power Supply: | 3.7 kw |

| Regular Operation Speed: | 5 - 7 meters/min for most plastic materials |

| Sheet Length: | 21.3"-39.4" (540 - 1000 mm) |

| Sheet Thickness: | 0.3 - 0.8 mm |

| Sheet Types: | Any material suitable for plastic card production |

| Sheet Width: | 9.8"-39.4" (250-1000 mm) |

| Tape Diameter: | 11.8" (300 mm) |

| Tape Position Accuracy: | +/- 0.15 mm |

| Series: | MTL-700NSA |

Related Products

-

Used USA 30 Ton Full Head Hydraulic Press (AP-10795)

Model: Used FH2463-30; 30 Ton; Quantity: 1.

-

Four Pillar Full Head Hydraulic Presses (FH – 80 Tons)

Regularly Kept In Stock

-

High Speed Die Cutting Press (HS-25 Tons) AP-10705C

Associated Pacific Machine offers a wide variety of automated die cutting machinery. Here are some of the…

-

Automatic Magnetic Tape Laying Machine (MTL-700M)

Machine For Roll To Sheet, Roll To Sheet and Roll To Roll, or Roll To Roll Applications

-

Manual Feed Magnetic Tape Laying Machine (MTL-700MS)

Machine For Sheet To Sheet Application